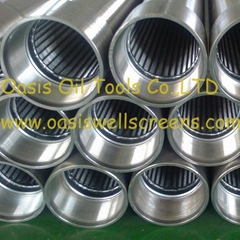

Continuous Slot Well Screen

BURGESS “EON” FIBERGLASS CONTINUOUS SLOT WELL SCREEN

COLLAPSE RESISTANCE GUIDE

Aqseptence Group Johnson Screens is the leading manufacture of screens in industrial filters, water well, architectural elements and the oil and gas market. In 1904, Edward E. Johnson founded Johnson Screens after developing the world’s first continuous slot wire wrapped screen to be used in a water well. A wide selection of precision-machined factory slot designs (.010'.125') with closely spaced inlet openings provides for uniform development over the length of the screen and proper stabilization of the gravel pack. Long Life Well rehabilitation costs are minimized, as PVC screens are inherently more. Locking Plug, (1.25) 1-1/4″ Orange Locking Well Plugs for Monitor Wells, T25 Well Plug, Torquer Style $ 4.85 Add to cart. Well Screen & Filtration Devices! Alloy Machine Works, Inc. Offers a wide range of products including stainless steel screen, sand control screens, well screen and services to meet your project needs. We specialize in helping clients save both time and money by utilizing state-of-the-art equipment and the latest technologies.

MAXIMUM COLLAPSE RESISTANCE PRESSURE (psi)

| SLOT SIZE | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 50 | 60 | 70 | 80* | 90* | 100* |

| SCREEN SIZE | |||||||||||||

| 4.5 In. I.D. | 600 | 580 | 560 | 540 | 520 | 500 | 480 | ||||||

| 6.5 In. I.D. | 415 | 400 | 385 | 370 | 360 | 345 | 330 | 315 | 300 | ||||

| 8.5 In. I.D. | 325 | 315 | 305 | 295 | 285 | 275 | 265 | 255 | 245 | ||||

| 10.5 In. I.D. | 260 | 253 | 246 | 239 | 232 | 225 | 218 | 211 | 204 | ||||

| 12 In. I.D. | 225 | 216 | 207 | 198 | 189 | 180 | 171 | 162 | 153 | ||||

| 16 In. I.D. | 185 | 165 | 145 | 125 | 105 | 85 | 65 | 45 | 25 |

* Slot sizes 80, 90 and 100 in 16″ I.D. are manufactured by special order only — “NO WARRANTY”

NOTES:

1. This chart is for quick evaluation of proposed installations. Use only for preliminary assessment.

The above specifications are designed for Burgess “EON” fiberglass continuous slot well screens. All specifications and properties specified above are approximate. Specifications and properties of material delivered may vary slightly from those given above. Burgess Well Company makes no representations of fact regarding the material except those specified above. No person has any authority to bind Burgess Well Company to any representation except those specified above. Final determination of suitability of the material for the use contemplated is the sole responsibility of the Buyer. Burgess Well Company sales representatives will assist in developing procedures to fit individual requirements.

uPVC & HDPE

We provide uPVC screen and casing for well drilling industry that meets the DWI specifications with the highest demands on quality. The product is specially designed for the needs of well construction.

We offer both flush and upsized joints in a range of lengths. Slots sizes range from 0.3mm to 3 mm and diameters from 35mm up to 400mm. Different wall thickness are available for varying depths of boreholes.

For abstracting water from formations where building a conventional filter membrane is difficult, we offer a uPVC screen pre-coated with a glued gravel pack.

For landfill applications, HDPE screen and riser is more applicable.

Clamps, filter socks, base and lifting plugs are available.

Stainless steel wire wrapped and laser slotted screens.

Weld wire stainless screen offers continuous-slot construction which aims to optimise flow rates, minimise clogging and help develop the water-bearing geological formations faster. Slot sizes as small as 0.1 mm and lengths up to 12 m are available.

Also available are laser cut steel tubulars with slot sizes as small as .3mm for horizontal well applications.

Borehole Sealants

For either decommissioning a borehole or backfilling the annular space between the casing the borehole walls, a range of bentonite and bentonite / cement products are available in powder and pellet form.

Filter Material

A filter pack is poured into the annular space between the screen and the borehole wall and serves to retain fine sand from the surrounding soil area. Quartz filter gravel for well construction is specified according to DIN 4924 and EN 12904.

The quality of the quartz filter gravel is an important prerequisite for the quality and durability of wells.

We provide a filter material that is:

- Natural quartz sand and quartz gravel

- Edge-rounded shape

- Free of organic impurities

- High quality due to state-of-the-art processing technology

Well Covers

A range of well covers are available from lockable flush covers to raised risers.

Continuous Slot Well Screen

Get In Touch

Efficient service, quality products and a great depth of knowledge.

Continuous Slot Pvc Well Screen

Call: +44 (0) 28 302 69522

Email:info@drillingsupplieseurope.com